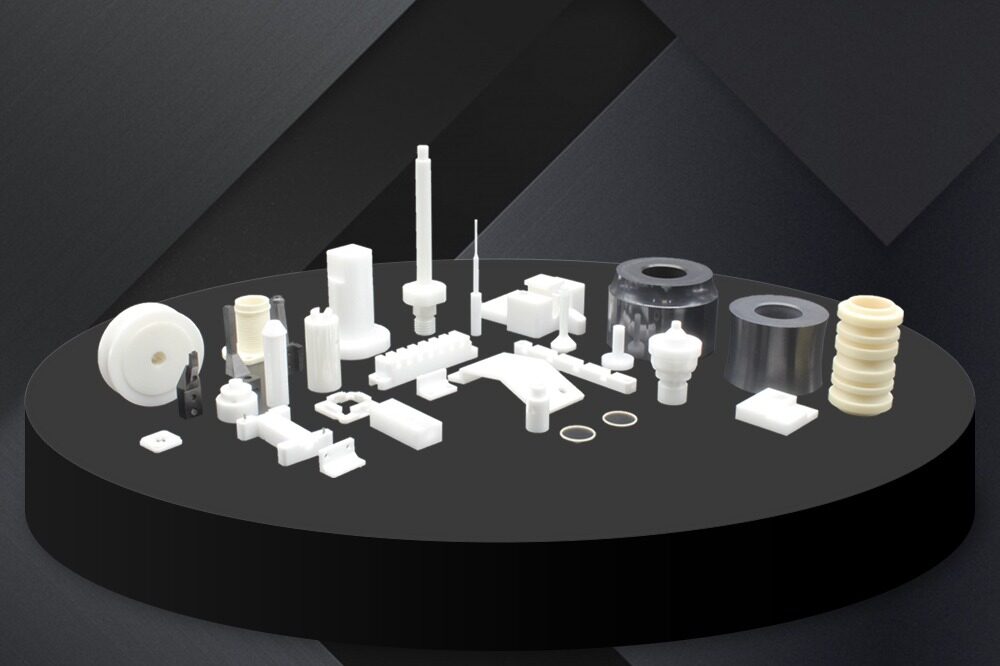

Strive to become ceramics, tungsten carbide, precision parts

Ideal supplier

CASE STUDIES

Widely used in medical devices, electronic devices, aerospace and other fields.

With excellent abrasion resistance, corrosion resistance and high temperature stability, it can meet the requirements of various working environments.

It is widely used in the manufacturing industry, especially in the automotive, electronics and machinery industries.

R&D and innovation capabilities have always been the primary driving force for the company's development

ABOUT ALLOYTEK

Since its establishment, alloytek has been specializing in the manufacturing and application of various tungsten carbide parts and precision ceramics. We have many years of professional application experience and leading solutions in metal stamping and forming, automotive manufacturing, medical equipment, new energy, semiconductor manufacturing, automation and other fields.

We will continue to provide our customers with tungsten carbide and ceramic products with outstanding performance and value, create new value for our customers, and strive to become a permanent and reliable partner of our customers to create a brilliant future together!

More than 10 years of focus on manufacturing

Over 300 partners

The company covers an area of

Serving over 1,000 clients

OUR VISION

By providing excellent service, we will help each customer get the most out of our products

News

NEWS CENTER

What are the manufacturing processes for wafer chucks?

The manufacturing process of wafer chucks is a complex and delicate process involving multiple steps and technologies. The following are some of the major manufacturing processes: 1. Material selection 2. Precision machining 3. Surface treatment 4. Heat treatment 5. Precision measurement and inspection

2024-10-25

Which industries are suitable for ceramic robotic arms?

Ceramic robotic arms show potential for a wide range of applications in several industries due to their unique properties, such as high temperature resistance, corrosion resistance, high hardness and low density. The following are some of the industries that are particularly suited to the use of ceramic robotic arms:

2024-10-25

Preparation method of colored zirconia ceramics

Colored zirconia ceramics are prepared by a variety of methods, the following are several common preparation processes: doping, sol-gel method, chemical vapor deposition (CVD) method, physical vapor deposition (PVD) method

2024-10-25

What is the pressure resistance of alumina ceramics?

Alumina ceramics have excellent compressive properties, which are attributed to their high hardness and good mechanical strength. At room temperature, alumina ceramics can reach flexural strengths of 300-600 MPa, while compressive strengths are even higher, usually above 1000 MPa.

2024-10-25